Technologies

December 2022

In the world of technical optics, the scattering of light on technical surfaces and inside materials results in a wide range of effects: on the one hand, certain conditions, for example objective lenses in imaging optics, can produce undesirable light reflections or ghost images. On the other hand, in illumination optics, light scattering can be used specifically for optimization, for example to homogenize light distribution. Helbling has developed a measurement setup specifically for such phenomena: its goniometer enables precise, time-efficient analysis and control in product development.es of highly sensitive sensors.

When light rays hit a surface, the direction of propagation usually changes. This depends, among other things, on the angle of incidence of the rays, the surface orientation, material properties, and refractive indices. In the case of a reflective surface, for example, the simple and often cited rule “the angle of incidence equals the angle of reflection” only applies in an idealized world. Most surfaces redistribute incident light in several directions. This is referred to as “light scattering”. Many applications benefit from this phenomenon, including indoor and outdoor displays, backlit displays, and control interfaces for devices and displays. With suitable light redistribution from a source, surfaces can be illuminated with homogeneous brightness. In the previously described examples, the sources are usually one or more LEDs. In other cases, scattering can become a disruptive factor, for example when light falls on the housing surfaces of highly sensitive sensors.

As an efficient development partner for optics and sensor solutions, Helbling Technik has designed a measurement setup that allows experimental determination of the light scattering characteristics of any material sample. This goniometer provides data quickly, at most within a few hours, which can then be used to directly optimize optical systems. It thus makes a valuable contribution to the development process. This approach has been successfully established at Helbling over the two years that the goniometer has been in regular use, as for example in the development of an illumination demonstrator (see cover image). Here, material characterization with the goniometer provided the necessary parameters to achieve the targeted brightness and light distribution on the first attempt, without the need for tedious reoptimization with multiple prototype samples.

The challenge: knowing the angular distributions precisely

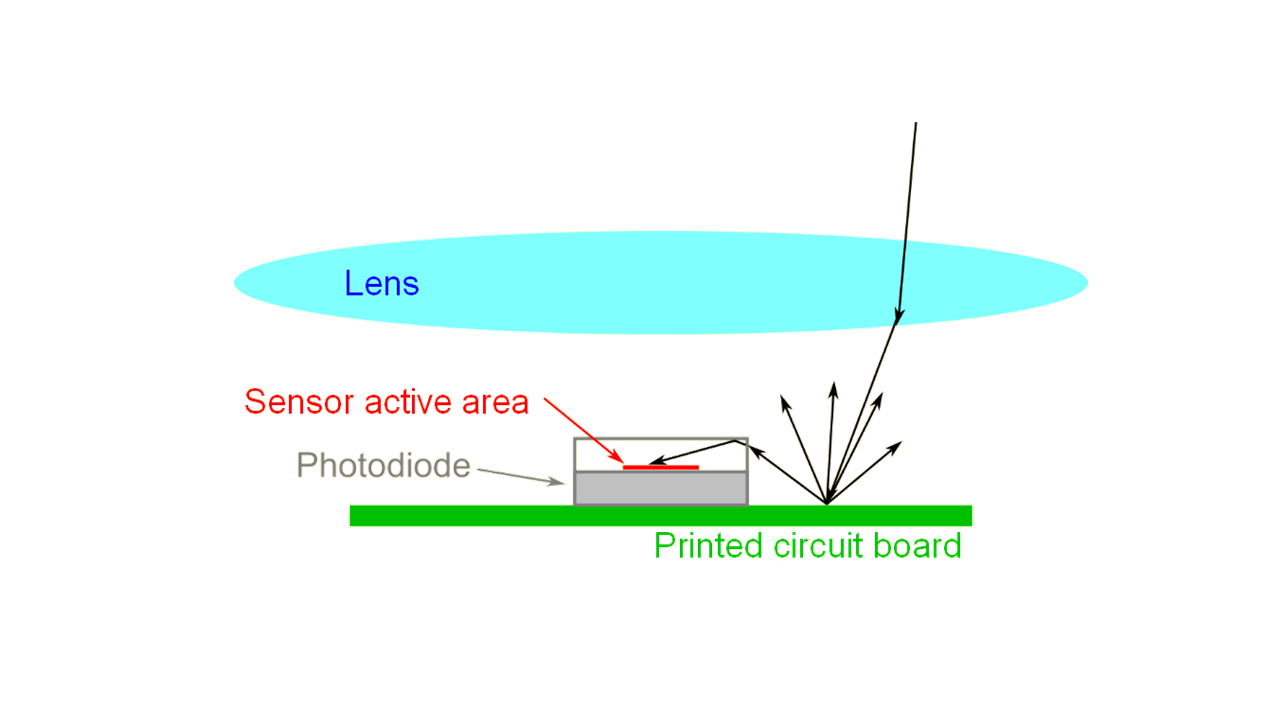

Figure 1 shows a situation from a typical development project at Helbling: depending on the angle and entry location, ambient incident light is scattered onto a printed circuit board and into a light sensor, such that a fraction of it falls upon the photodiode and generates a parasitic signal. This can occur inside or around the housing and leads to an error in the data measured at the sensor. In these cases, light scattering on the adjacent surfaces must be considered in more detail when designing the system.

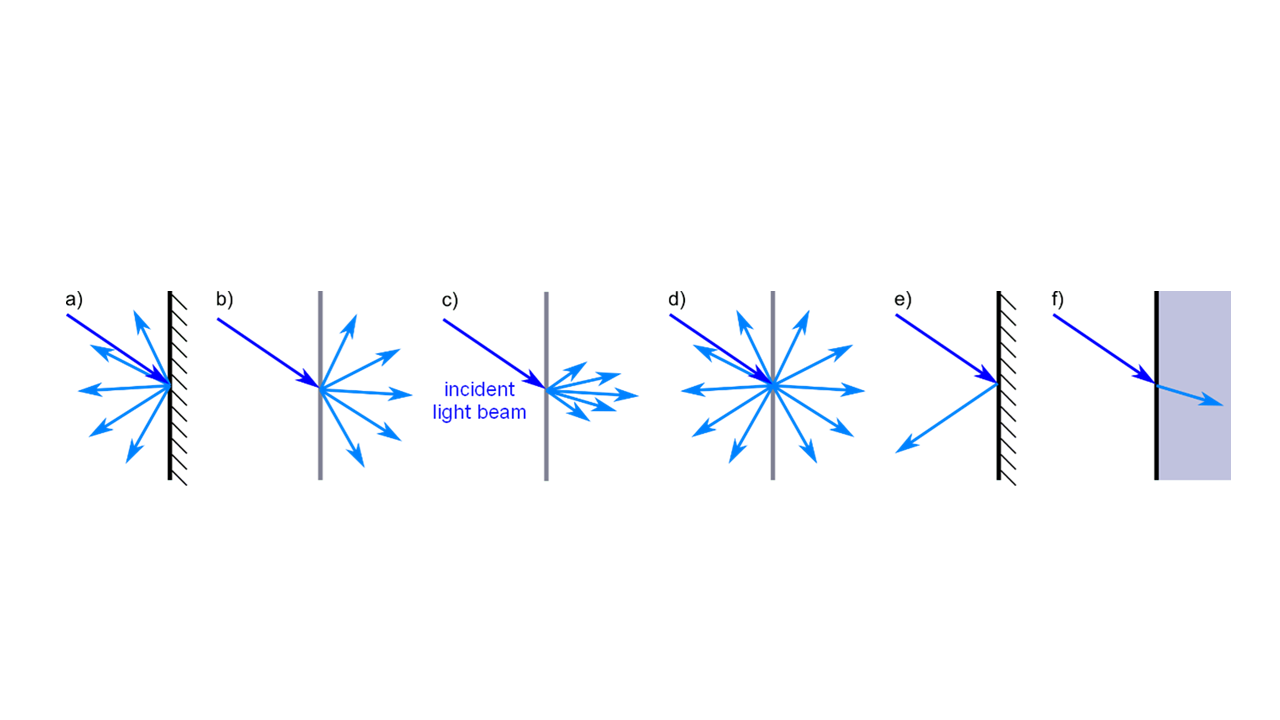

Regardless of whether light scattering occurs intentionally or unintentionally, it can be essential when developing an optical system to know the angular distribution of the deflected light rays. Figures 2 a-d illustrate a few possible characteristics. They can be roughly divided into two categories: diffuse scattering, characterized by a relatively broad angular distribution (Figs. 2a, b, and d), and specular scattering, in which the deflected rays spread in a narrow range around the main beam (Fig. 2c). In practice, a mixed form of both models usually occurs, and even experts can hardly determine the scatter type present and in what proportion based on visual impression alone. The solution is the bidirectional scattering distribution function (BSDF): it provides an exact mathematical description of the entire angular distribution of the scattered rays depending on the material and the surface finish, among other things. However, unlike classic reflection (Fig. 2e) or refraction (Fig. 2f), theoretical representation is generally complex.

Helbling’s solution: the goniometer

With the goniometer, Helbling Technik has established an alternative procedure: the BSDF of a material can be determined experimentally in the optics laboratory using a measuring device specifically designed for this purpose. The measurement can be performed purely as a service to characterize materials and surfaces, for example to check available data independently. However, it is particularly valuable in a development process. The BSDF data is directly integrated into optical simulations via a ray tracing software such as LightTools. A development engineer can then precisely characterize the optical system and optimize it for desired target values. Experimental iterations are thus obsolete, massively reducing development time. Experimental BSDF measurement can be done with reasonable effort thanks to good automation.

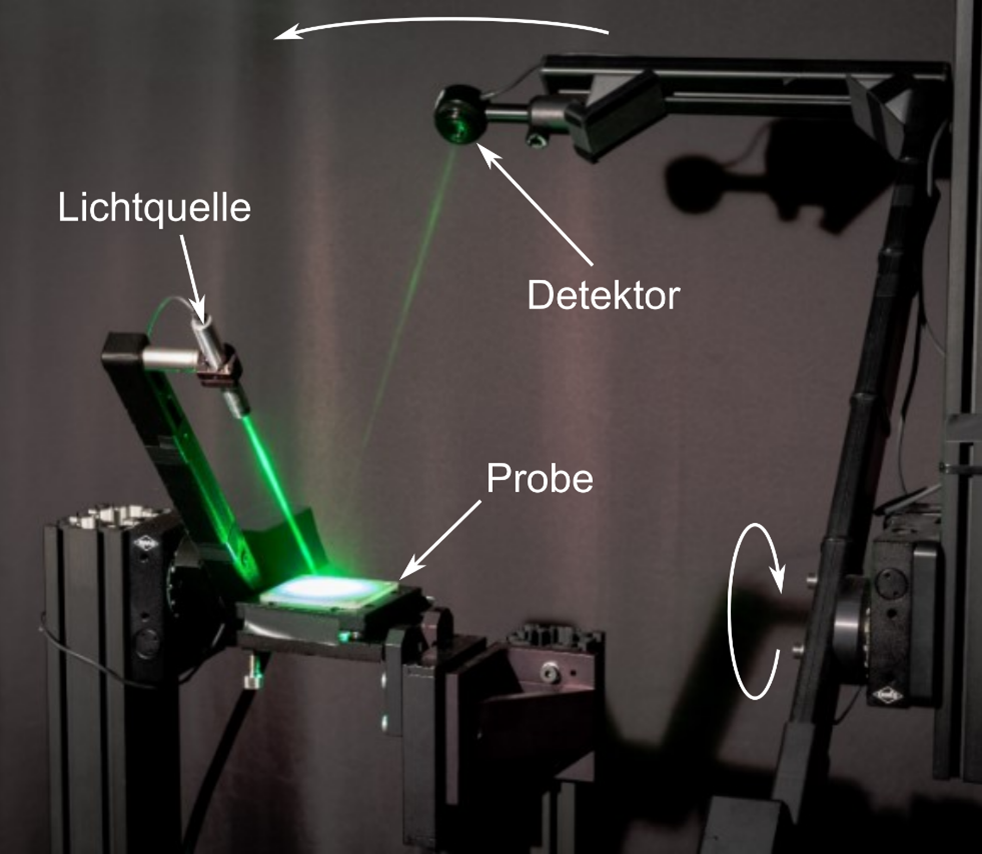

The goniometer setup in the Helbling optics laboratory is shown in Figure 3. It contains a detector for measuring the power of the scattered light and an exchangeable light source, here a green laser diode module, which illuminates the object to be characterized. The latter is fixed on a sample holder. For the BSDF measurement, the detector rotates on two axes around the target while the light intensity is measured.

The image shows the configuration for determining the reflected intensity as a function of the two angles described by the bidirectional reflectance distribution function (BRDF, see also Figure 2a). Similarly, the measurement can also be performed in transmission mode. In that case, the target is illuminated from below. This provides the bidirectional transmission distribution function (BTDF, see also Figures 2b and 2c). The combination of all the measurement data results in the BSDF (Fig. 2d). Due to automation of measurement and evaluation algorithms, once the sample is positioned, the results are available within a few minutes up to a maximum of a few hours, depending on the required resolution. In line with the project’s needs, the data is prepared either to be used in optical simulation software such as LightTools or for examination by the project team. Specific material parameters like relative transmission or the half peak angle can be calculated. They are suitable for material or surface evaluation.

The potential: one technique for illumination modules and a wide variety of questions

When characterizing diffuse materials, the parameters of a Gegenbauer function can also be determined from the measurement data. This mathematical model commonly used in illumination optics helps to describe the scattering of light in a volume. In contrast to scattering on a surface, the angular distribution here also depends on the thickness, or optical path length, as the light passes through the sample. Such materials are used, among other things, in illumination modules or displays.

In addition, Helbling’s goniometer has been designed to be easily customizable: the properties of the light source, such as its spectrum or the size of the light spot on the measurement sample, can be adjusted. Additionally, simple modifications allow direct measurement of the angle-dependent characteristics of light sources or detectors.

Summary: the goniometer speeds up the development process

The goniometer has proven itself as a measuring tool for everyday product development. It accelerates the development process, particularly because measurement results are readily available in few minutes or hours. In addition, its use significantly increases the validity of optical simulations since relevant aspects of the simulation can be based on measurements instead of assumptions. For the development of illumination optics, the extraction of the Gegenbauer parameters also has been proven to be extremely valuable in several projects: only a few steps are required to reach the optimized system. This enriches Helbling’s development services portfolio in order to tackle future challenges.

Authors: Johannes Eckstein, Andreas Liehl, Helen Wächter

Main Image: Helbling