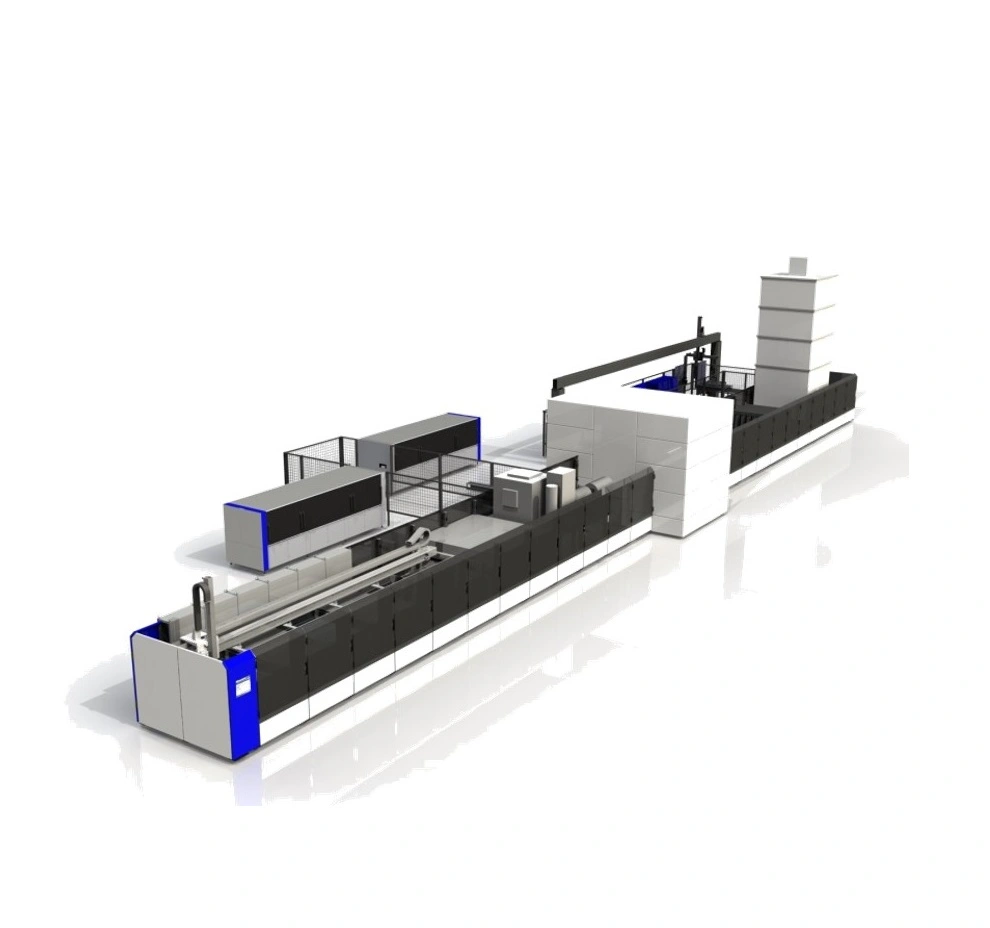

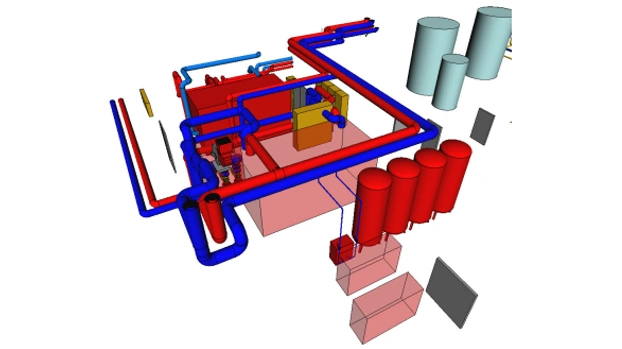

Project

Digital Development Process Support

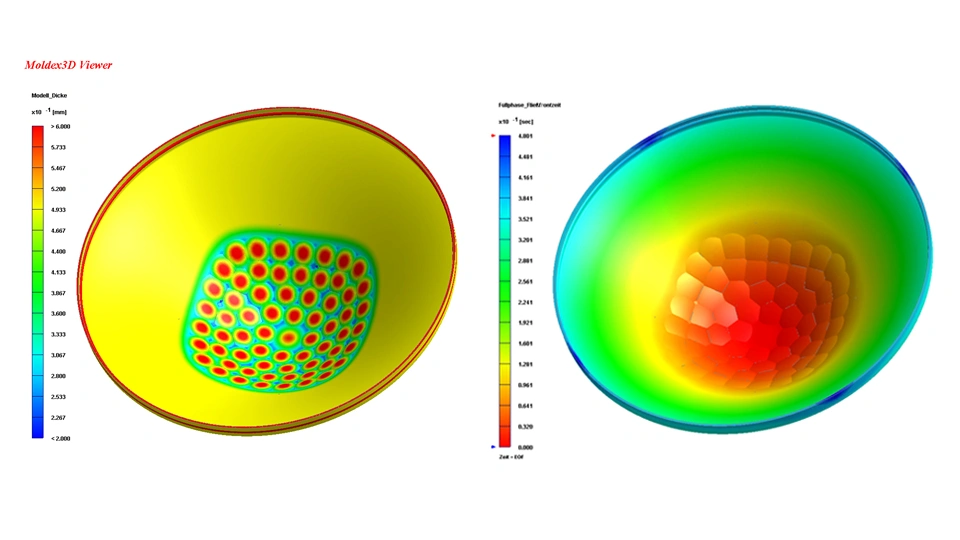

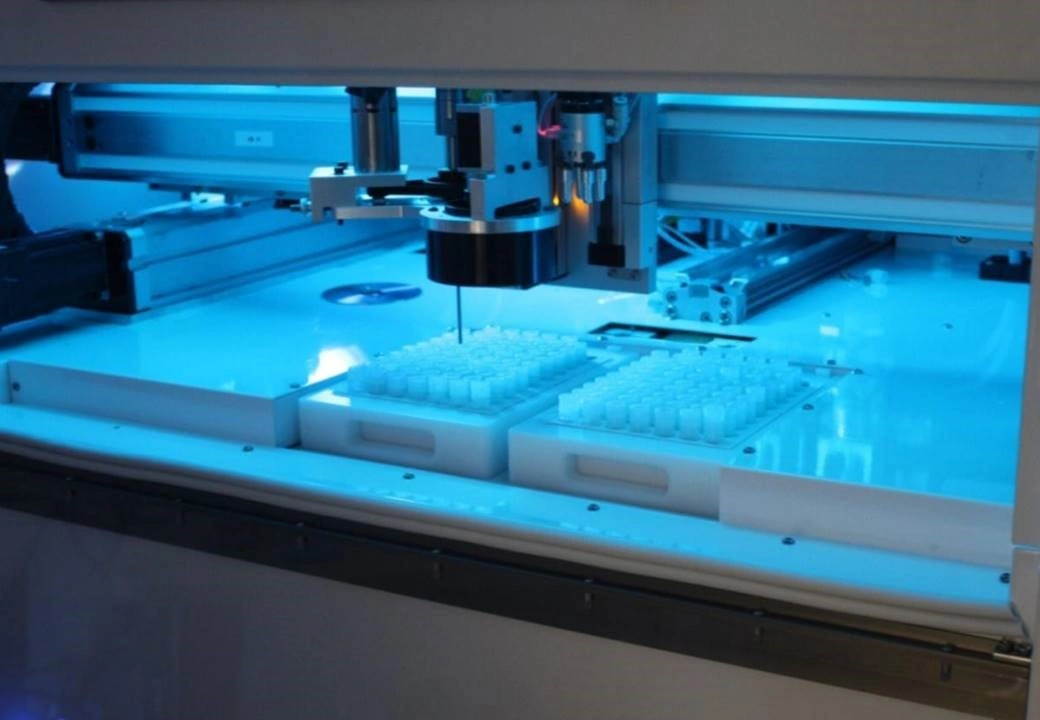

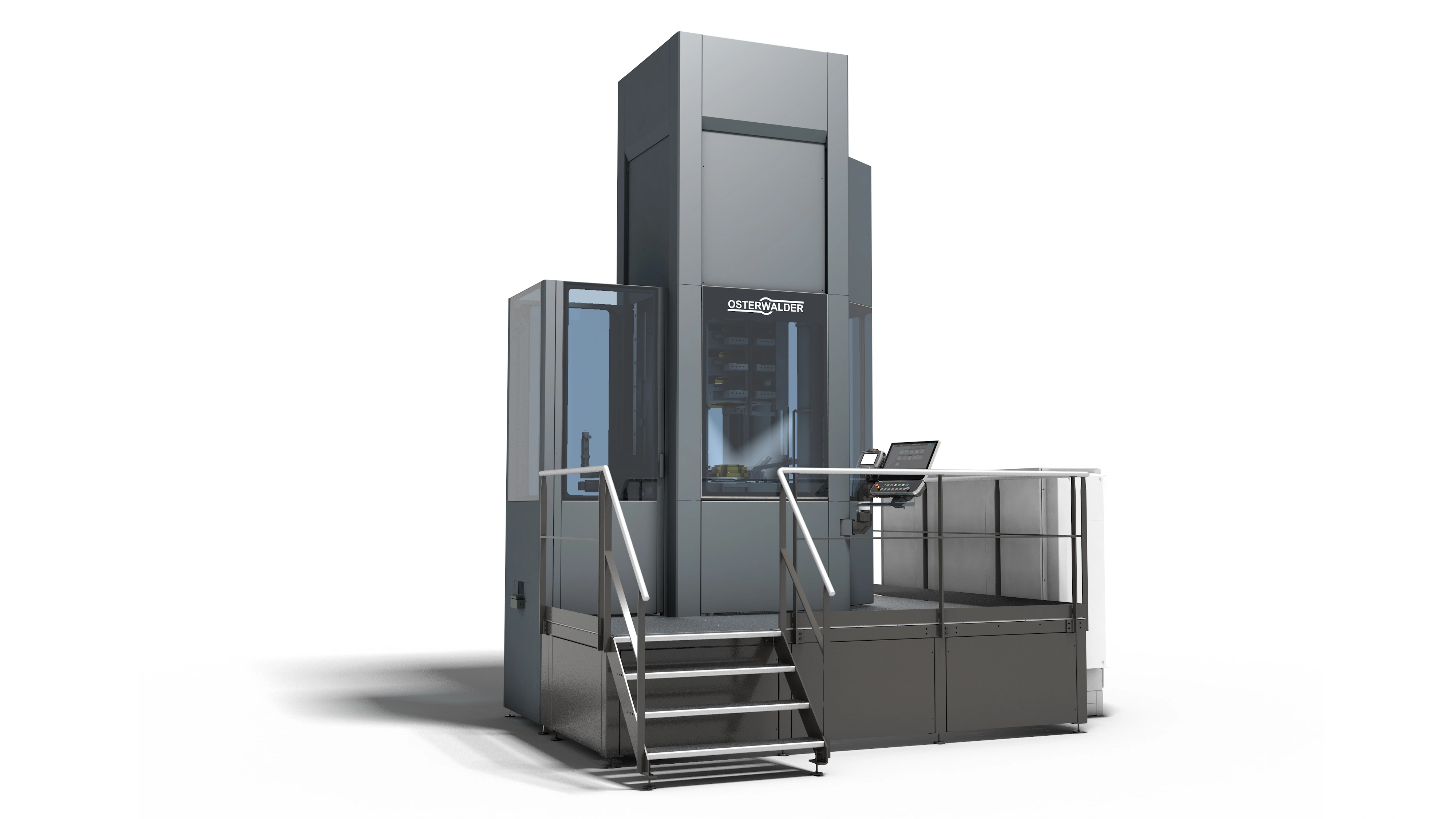

The world-leading Chocolate Mold Manufacturer’s Development Processes have been optimized to faster satisfy customer needs and to further expand their competitive advantage.

- Industry: Mold and Tool Manufacturing

- Revenue: CHR 7,5 Mio.

- Headcount: 50

- Locations: Rupperswil

Services

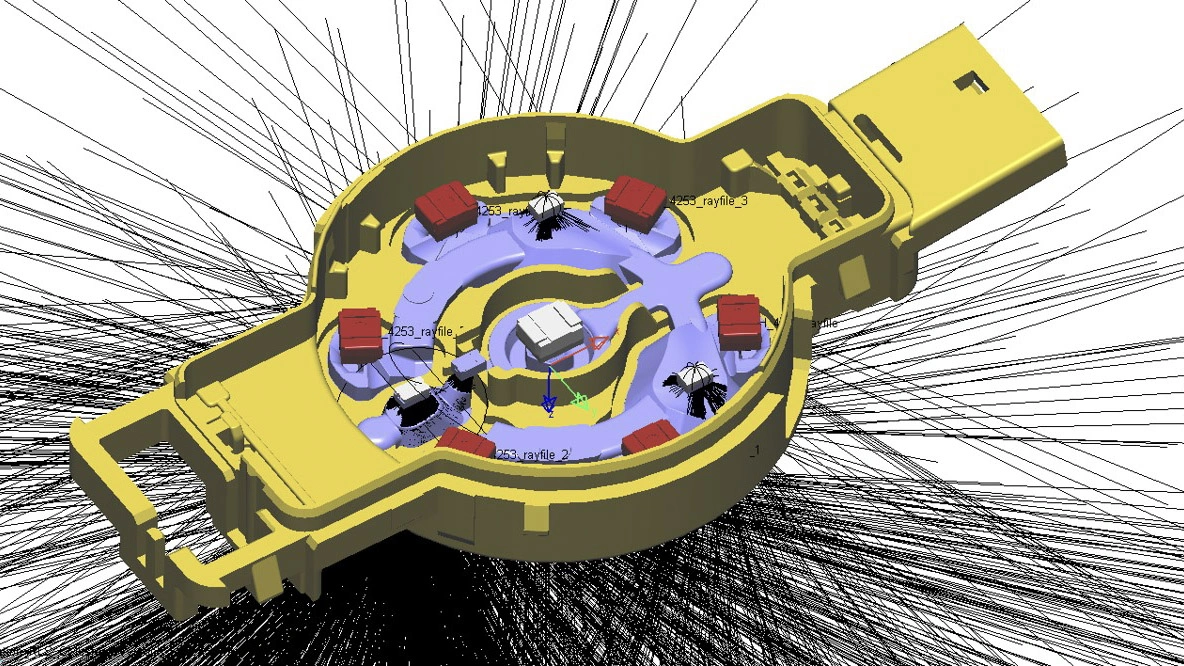

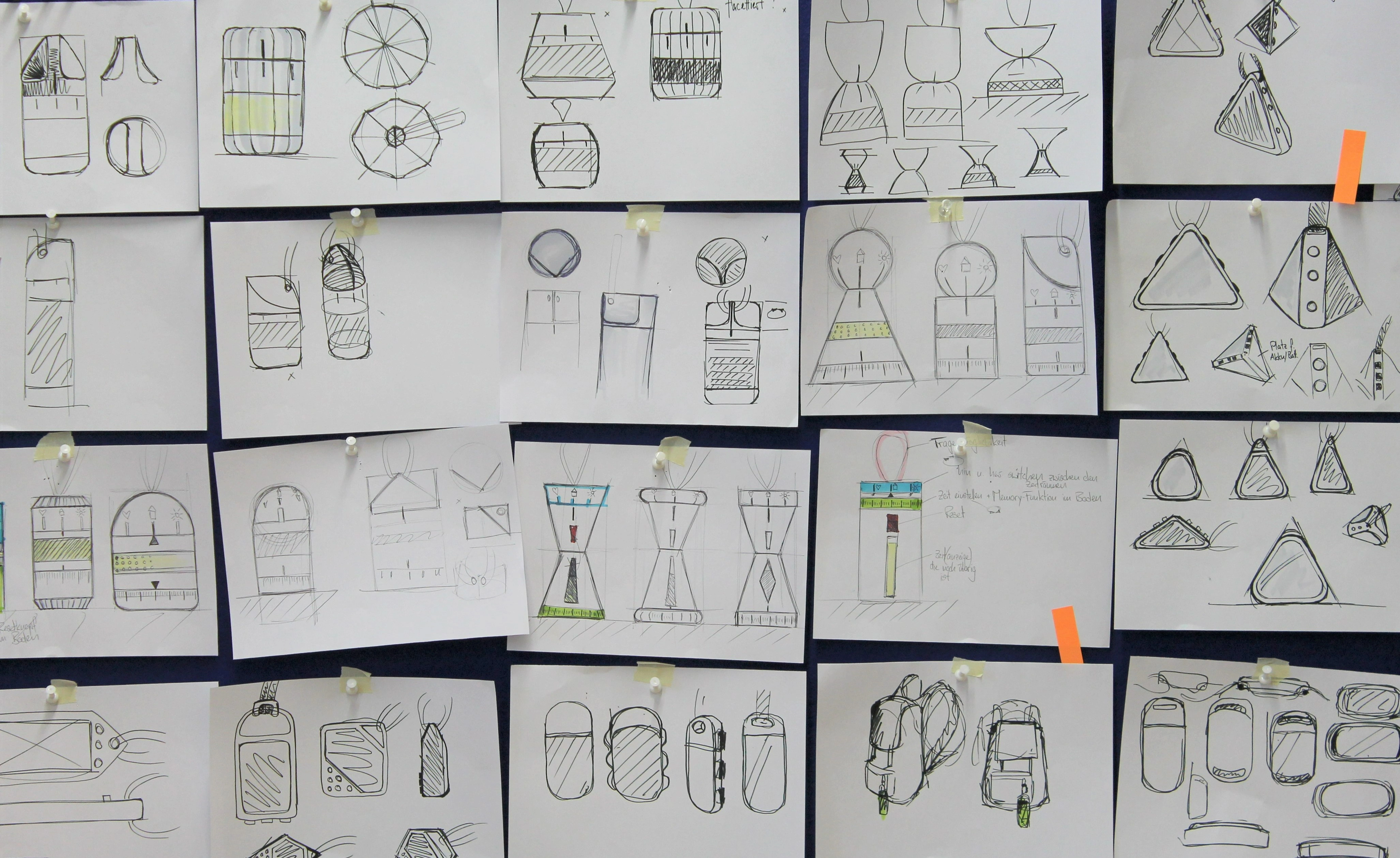

- Process and Methodology Consulting

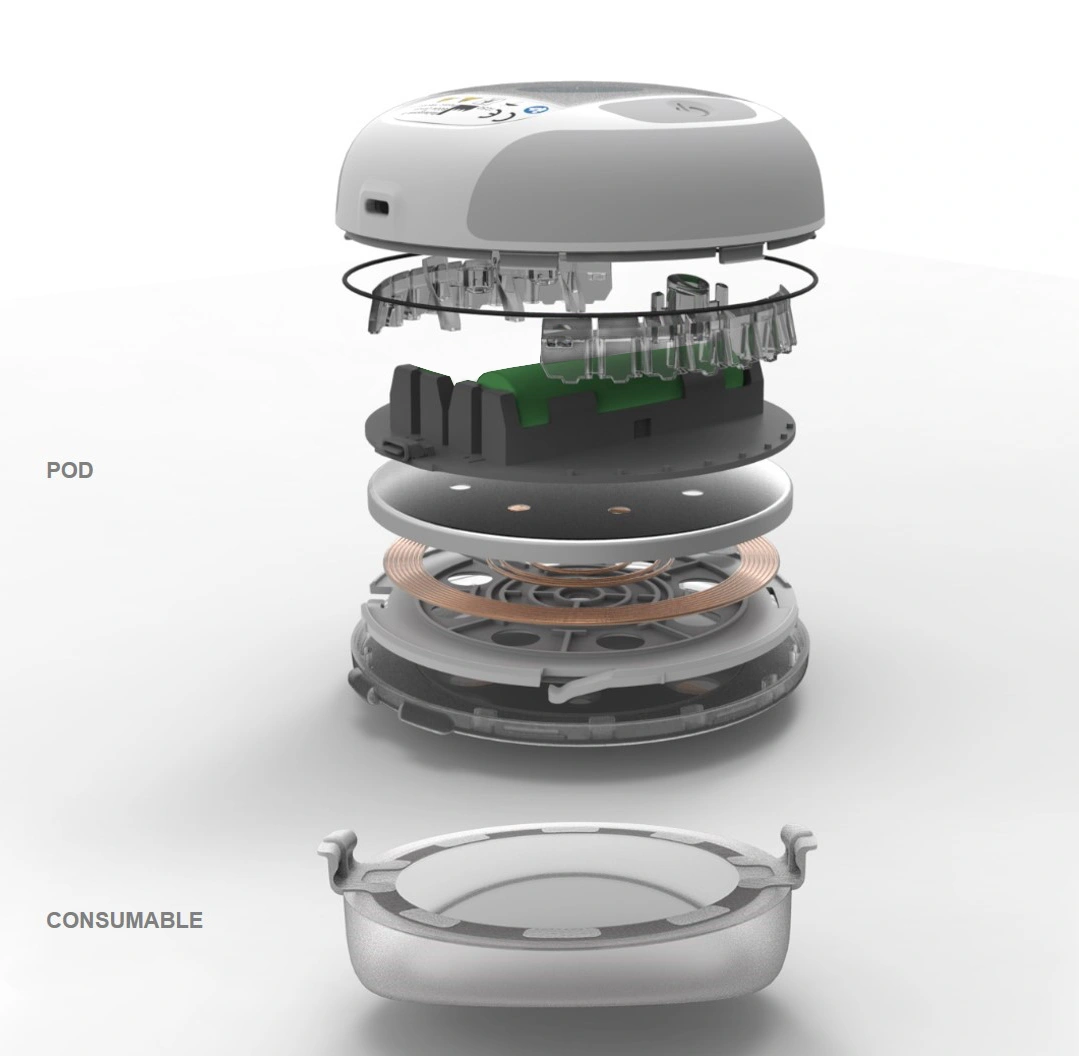

- Provision and Maintenance of CATIA CAD in the 3DEXPERIENCE Platform

- Key User Training

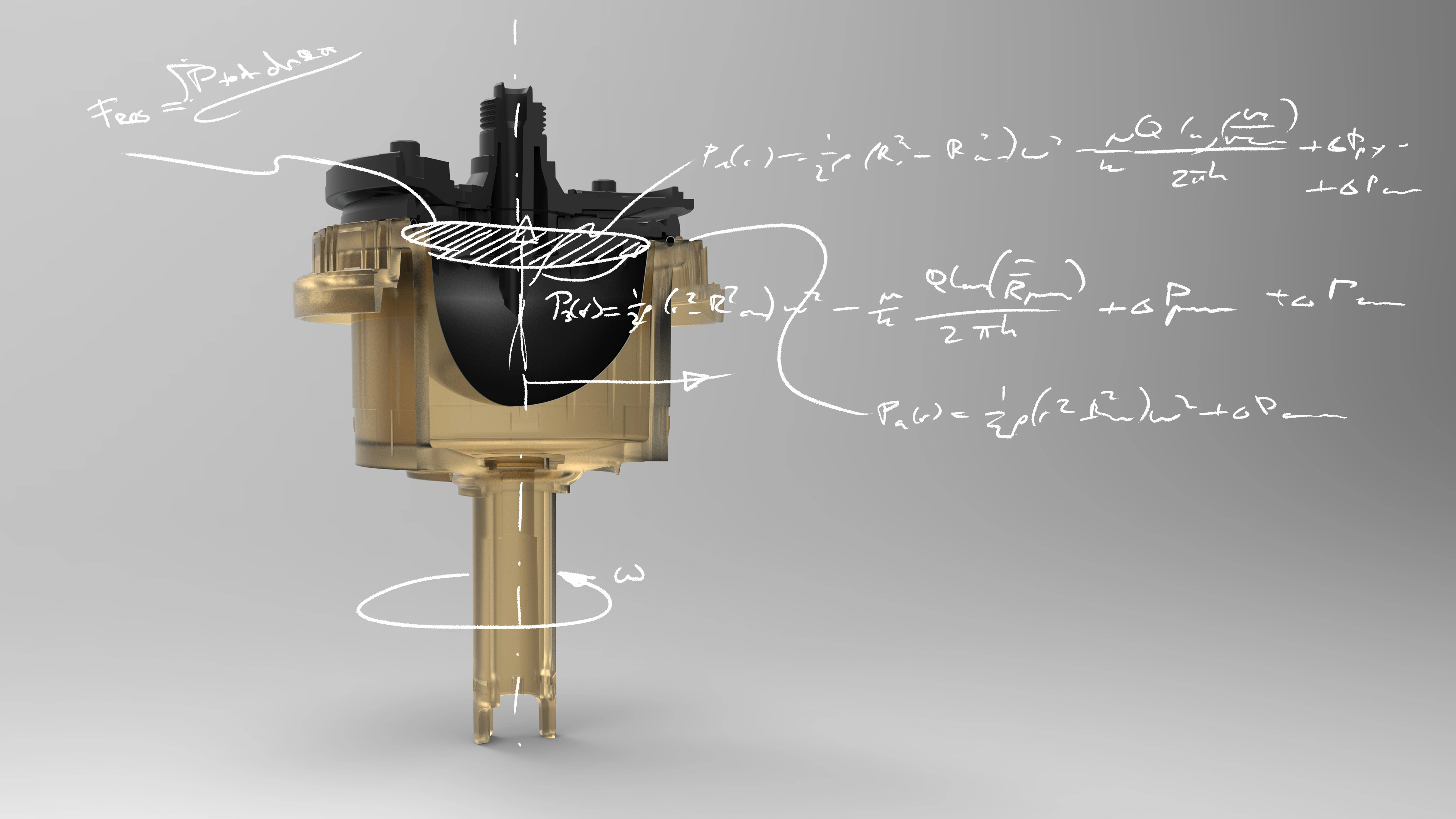

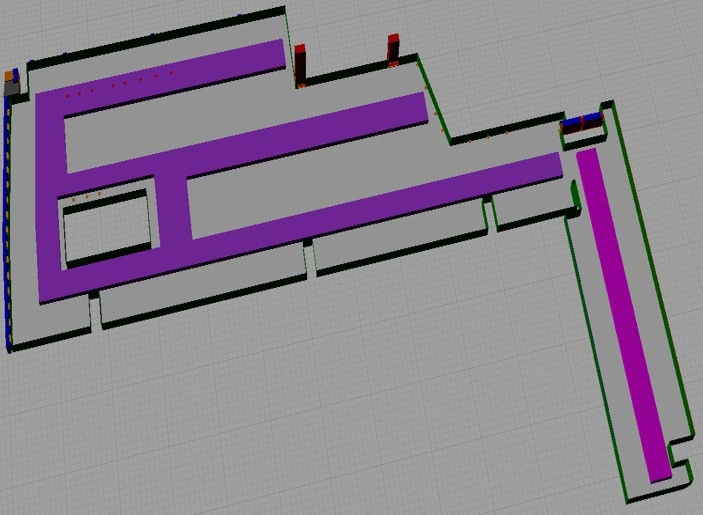

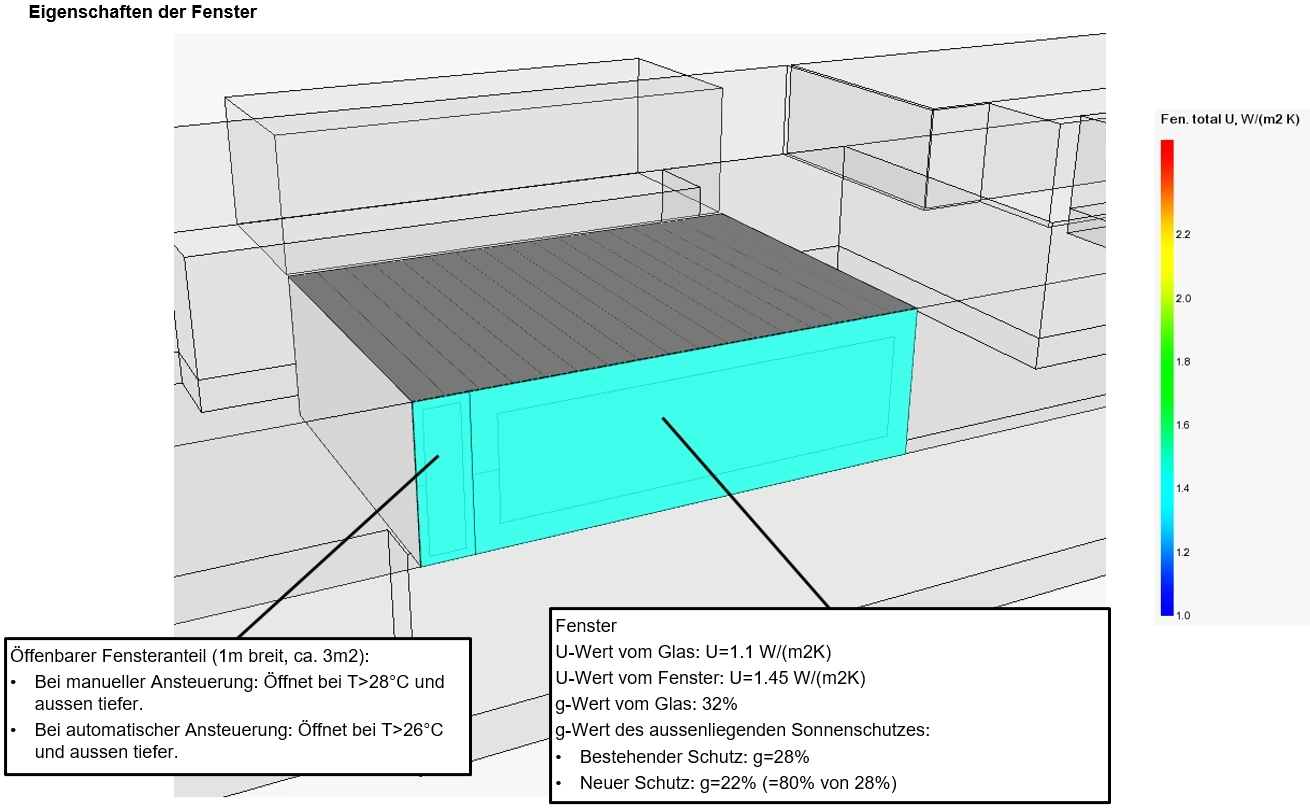

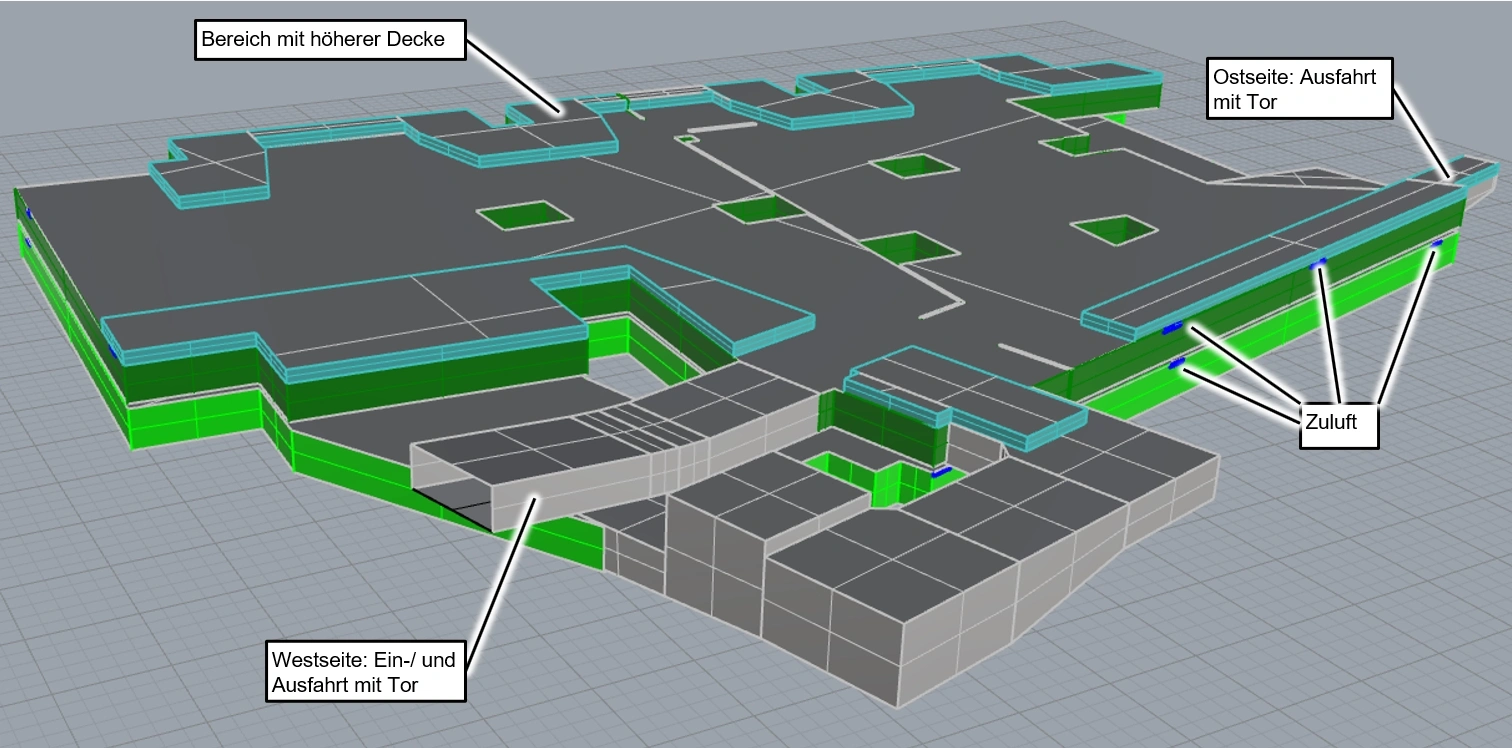

- Automation solutions: Starting from the customer’s chocolate net shape, the integrated parametric solution generates the injection mold for the final chocolate mold.

Result / Success

- Development Process Optimization for faster accomplishment of customer needs

- Competitive advantage increase

- 50% time saving in Design and Construction resulting in substantially faster project completion.

Cases

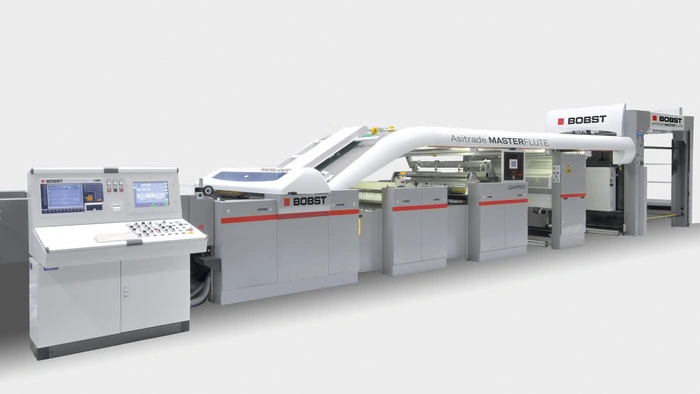

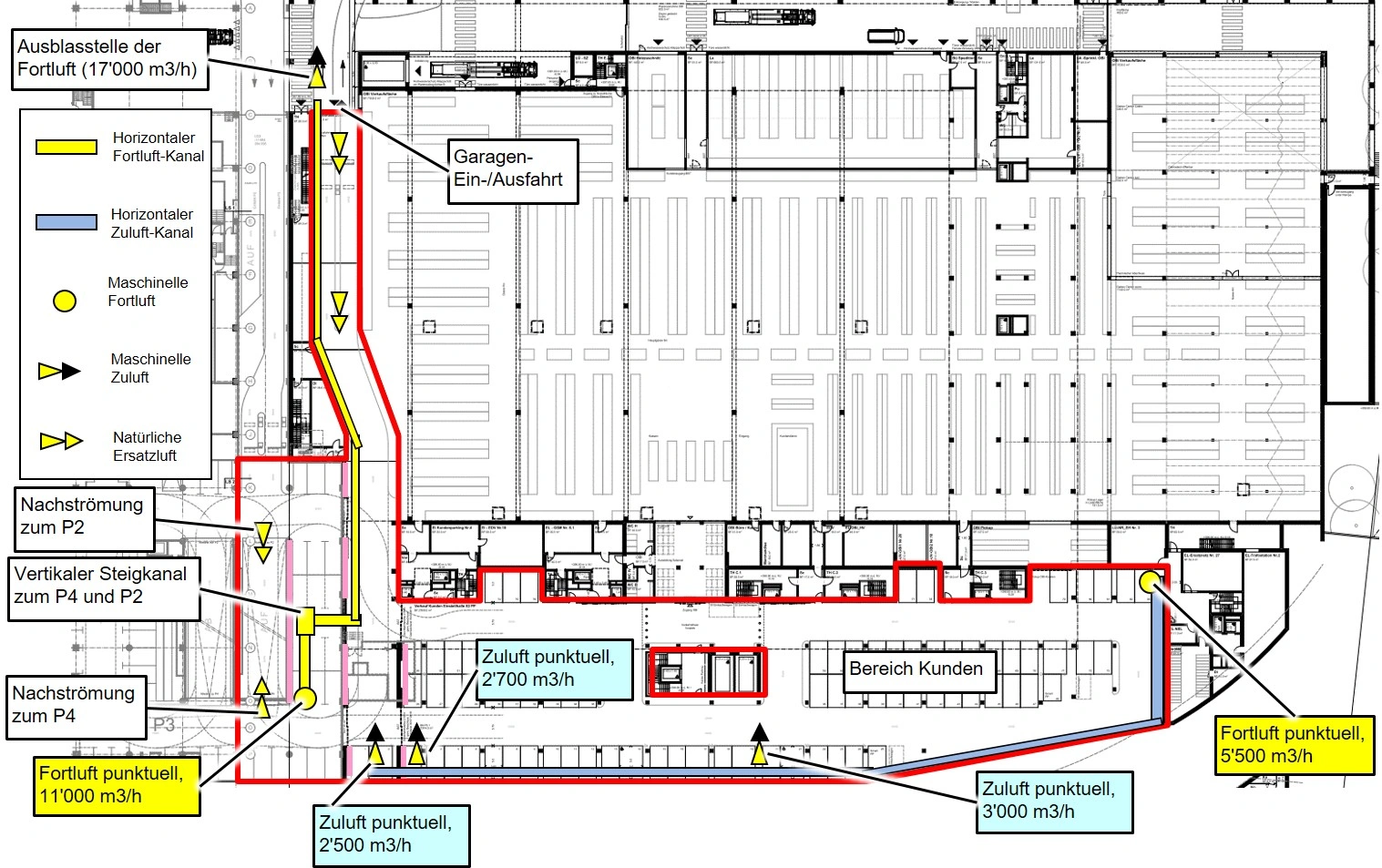

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

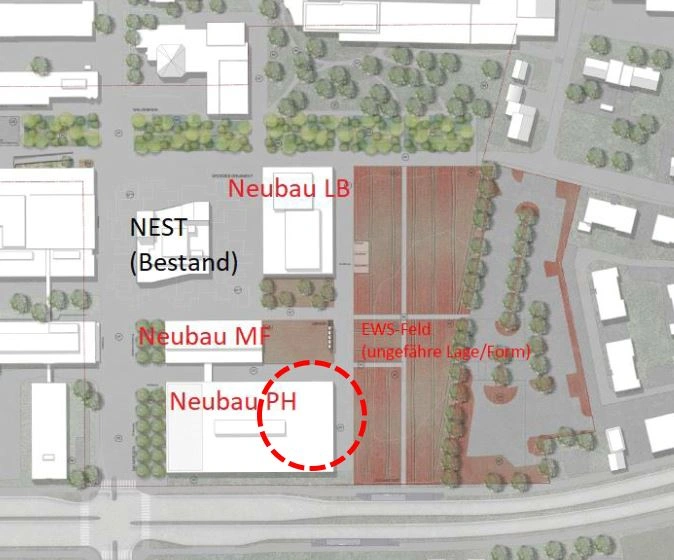

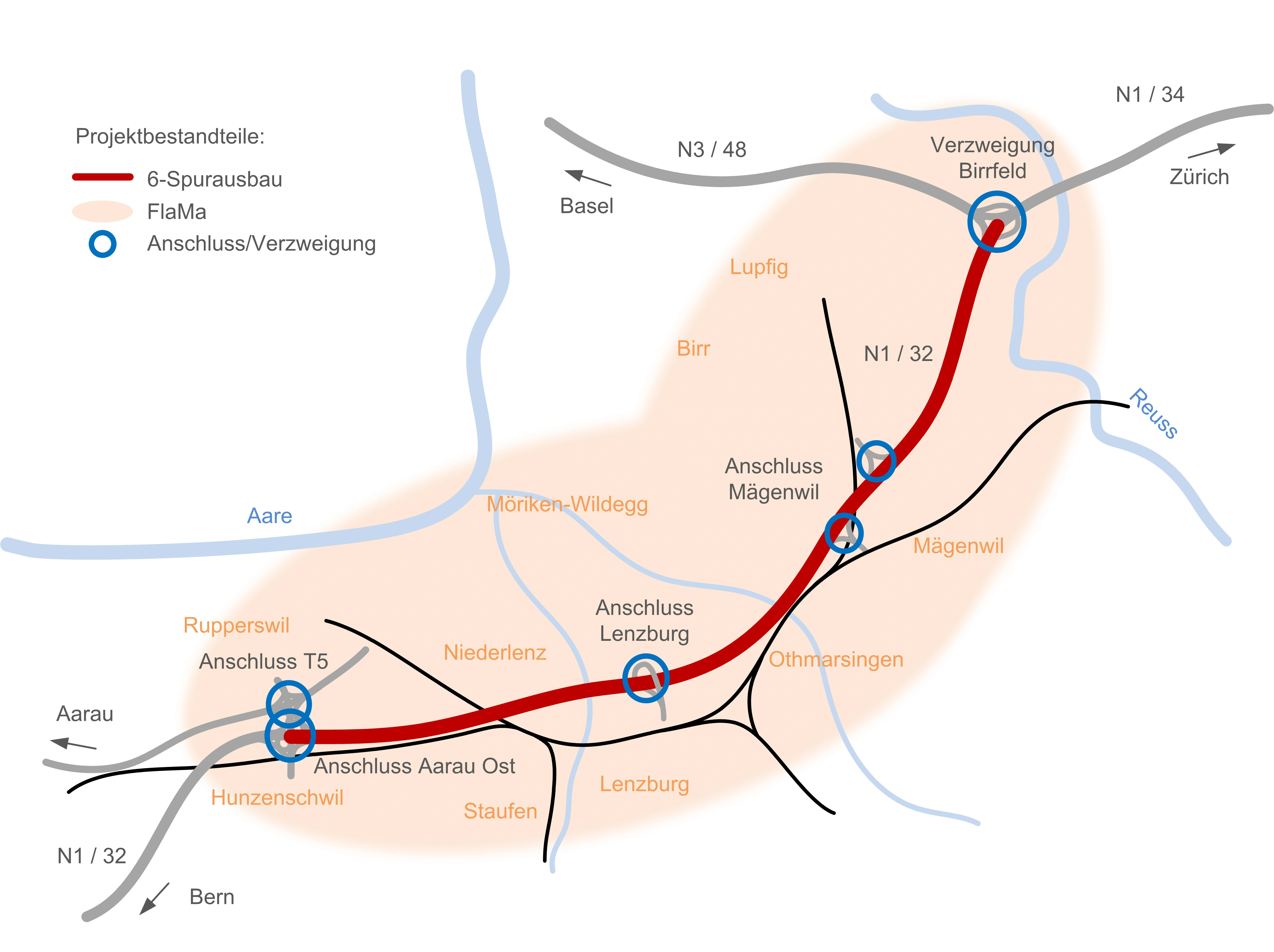

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: