Project

iOS and Android App for BTLE-based Data Exchange

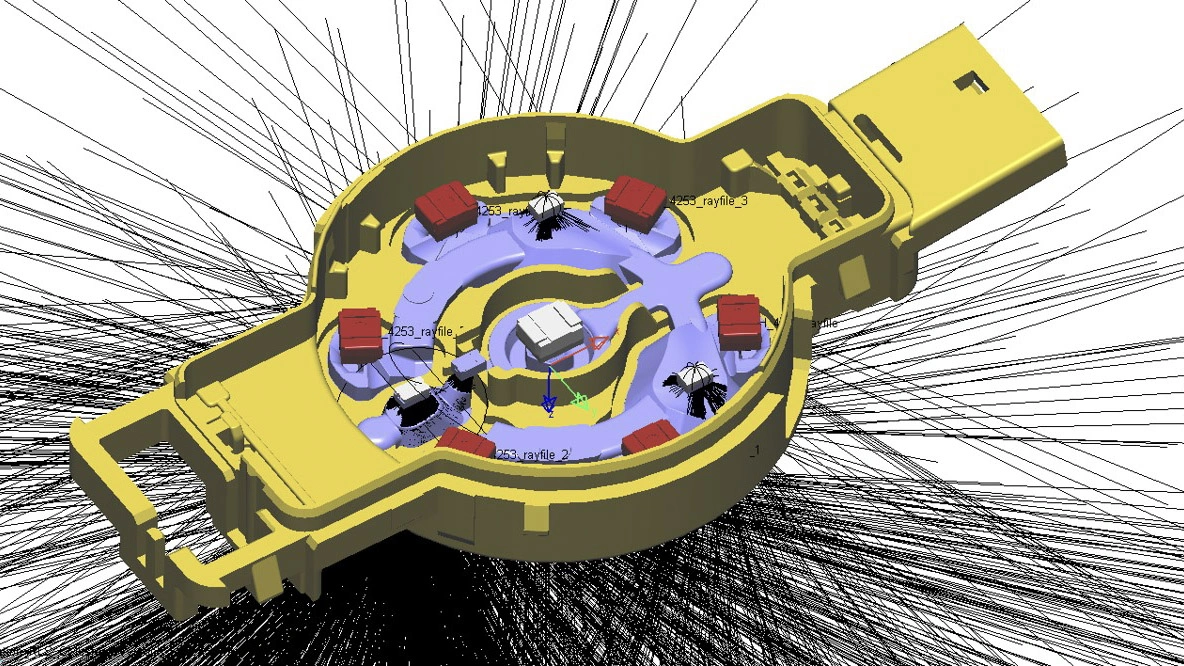

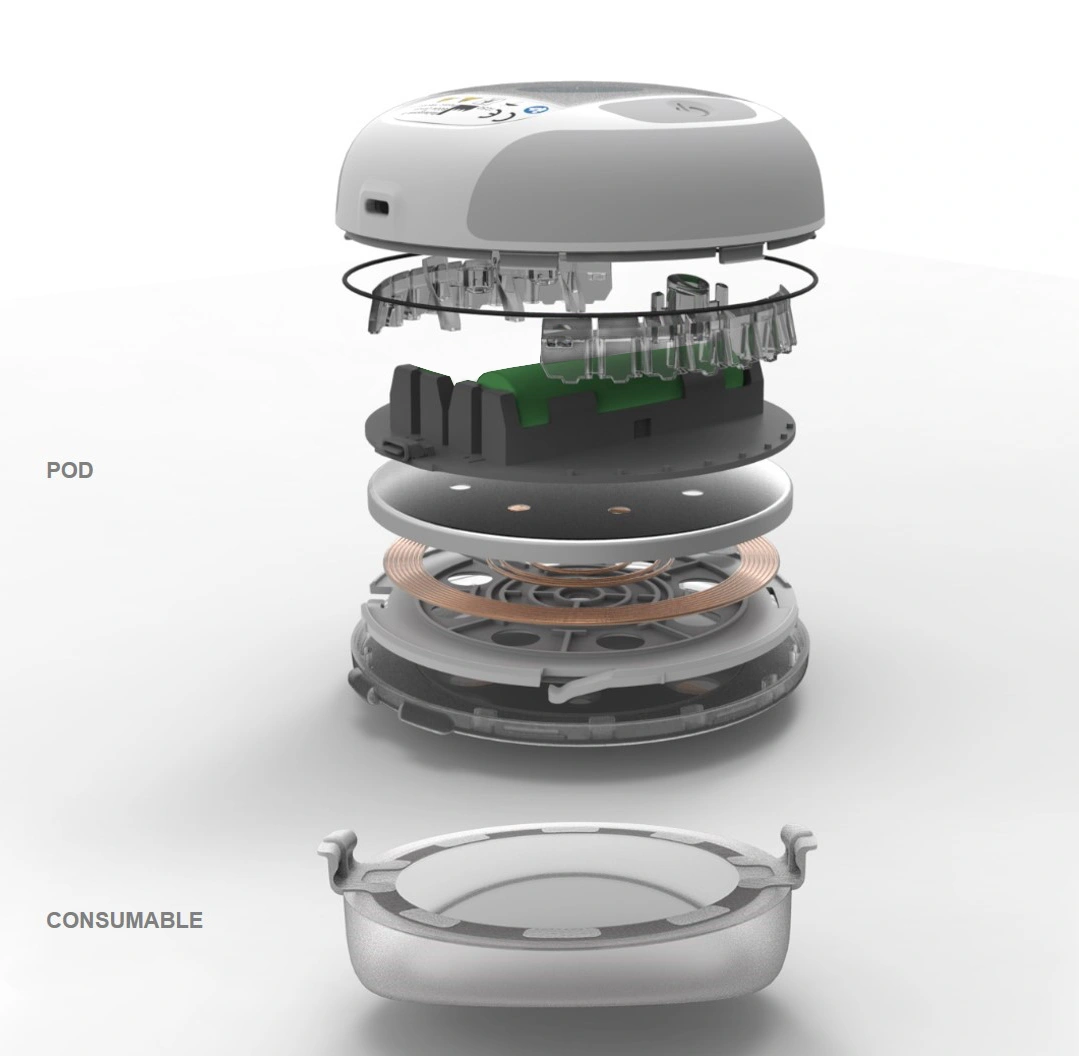

A manufacturer of home appliances planned to bring an app to market that would allow one of its devices to be controlled via Bluetooth. To achieve this, Helbling developed the lower software layers (API) needed for the connection and data exchange via Bluetooth Low Energy (BTLE). An interdisciplinary team made up of app development specialists, software developers and electronics engineers was needed to quickly create the BTLE interface and implement device-side services in close cooperation with the manufacturer. Since Helbling unites all of these skills under one roof, it was able to assemble a project team of experienced experts within a short period of time.

- API for iOS and Android OS, developed in Xcode and Java

- Supports Bluetooth 4.0, pairing, advertisement, event notification

- Supports a variety of services

- Seeks BTLE-capable appliances and displays found appliances

- Establishes a connection to an appliance

- Reads the appliance settings and statistical data

- Saves settings in the appliance

- Saves user data in the appliance

- Establishes a connection to a server to store data in a cloud

Services

- Define and elucidate starting situation: Usability, requirements for app and software for networking and data exchange via BTLE

- Including all stakeholders in the process, from electronics experts to embedded software specialists and the customer's marketing

- Clarifying security standards through authentication and other security elements

- Delivering all relevant test case

- Developing a solution for trouble-free software update

- Defining command interfac

- Defining software architecture on this basis

- Core service: programming software with cutting-edge development methods and tools

- Extensive verification with own version of app on bottom-up principle

- Preparing code as API

- Transferring software library and comprehensive software documentation

Results / Success

Helbling developed the API on schedule and met each of the customer's requirements in full. The customer was then able to implement it directly in its app.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

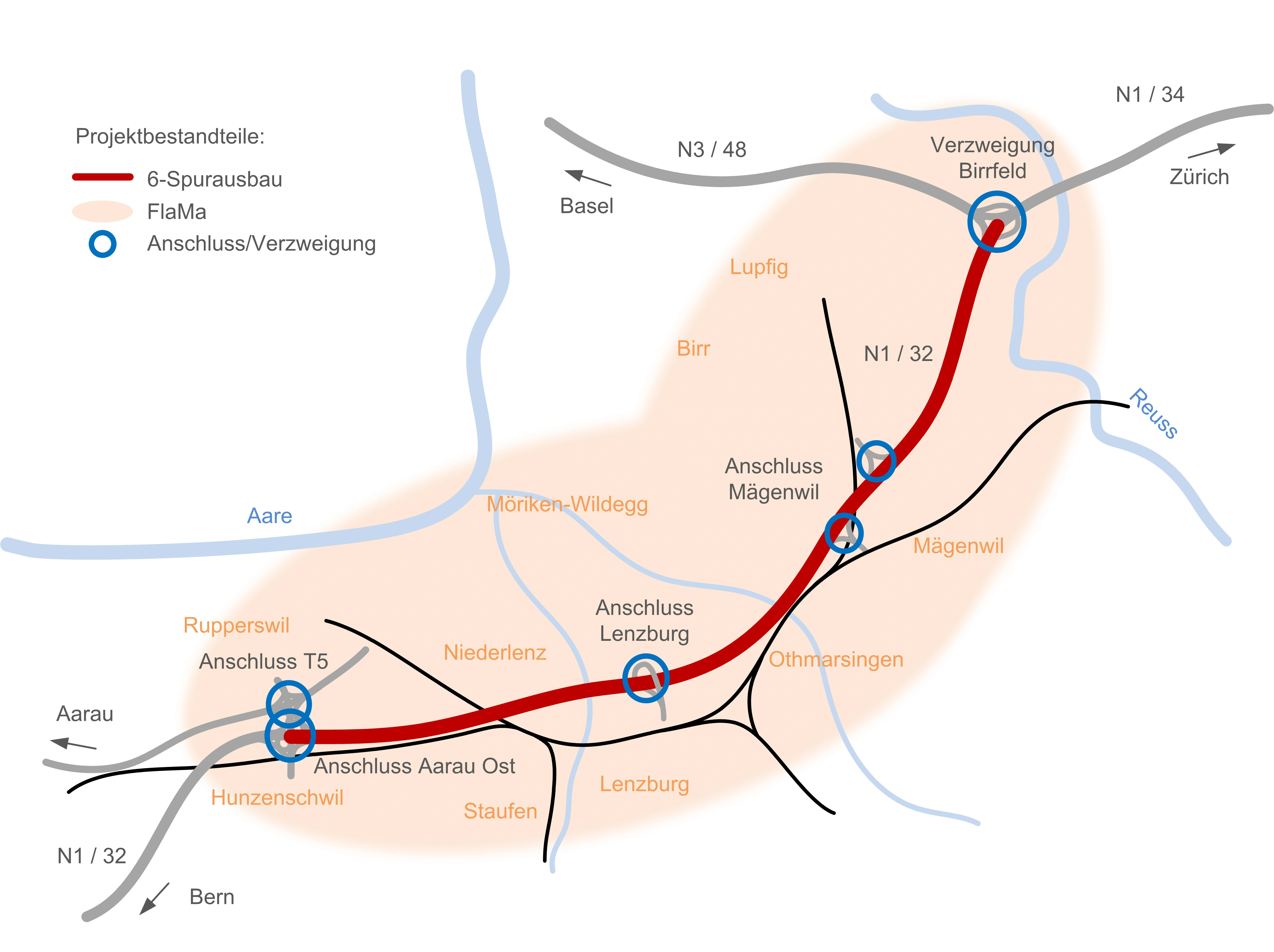

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: