Microplastics are a largely invisible threat to humans and the environment, the consequences of which are considered to be dramatic. An increasing number of legal measures at international level are therefore aimed at containing the threat posed by the emission of microplastics. Helbling works with its clients to develop innovative solutions in this area that cover the entire life cycle of a product. One particular focus is on water filtration and the local separation of microplastics.

Plastics are omnipresent in everyday life. They can be found in packaging materials, electronic devices, and even synthetic clothing. All of them are made entirely or partly from petroleum-based plastics. The advantages are obvious - plastics are easy to mold and therefore versatile. They are also easy to handle, inexpensive to produce and durable. However, it is precisely this longevity that becomes a problem when plastics end up in the environment. Firstly, the plastics take several hundred years to decompose, and secondly, abrasion produces plastic fragments that cause considerable problems for humans, animals, and the environment. These are the microplastics that we are talking about. Reducing the volume of microplastics as much as possible in the future is one of Helbling's goals. This is being achieved on the basis of an eco-design approach during product development, while interdisciplinary specialists from the areas of process development and process engineering are working on innovative projects, particularly in the area of household goods.

What are microplastics and why is it problematic?

Microplastics are water-insoluble plastic particles with a maximum diameter of five millimeters. According to estimates by the International Union for Conservation of Nature (IUCN), around 3.2 million tons of microplastics are released into the environment every year, around half of which end up in the world's oceans. Microplastics can today be found almost everywhere in nature. A considerable volume of microplastics also enters the human body through food intake: According to studies, an average of five grams of microplastic particles per person per week. This weight is roughly equivalent to that of a credit card[1]. This is certainly a cause for concern, as microplastic particles serve as a vehicle for bacteria and viruses. If these are absorbed in the digestive tract, it can lead to changes in the composition of the intestinal microbiome, which is associated with various metabolic diseases. The exact health effects are currently being investigated in studies.

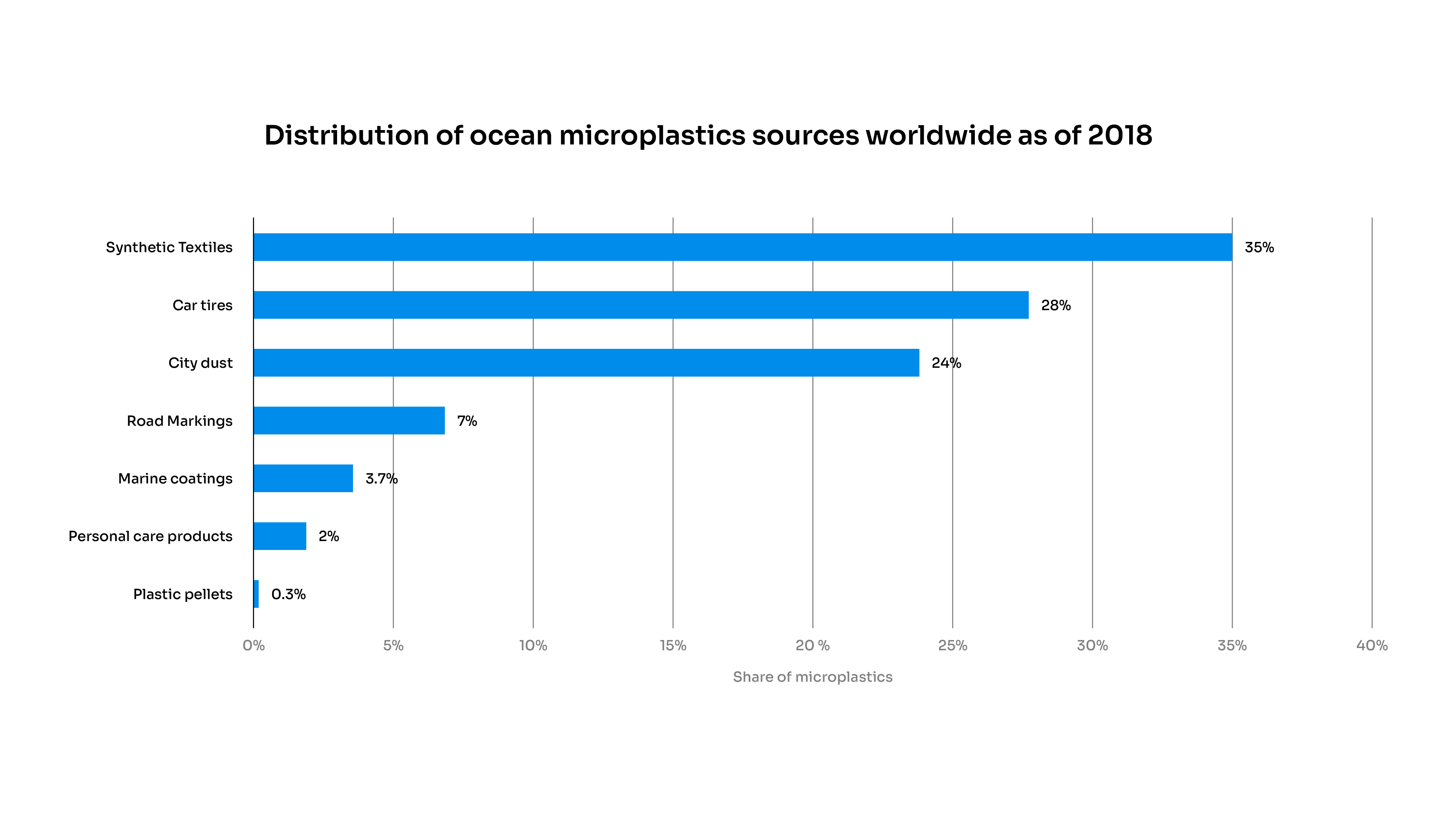

Where do microplastics come from?

Plastics are used in a variety of applications, and the resulting origins of microplastics are therefore highly diverse. A basic distinction is made between primary and secondary microplastics:

- Primary microplastics are plastic particles that are deliberately produced as such. They are used as binders or carriers for active ingredients in many cosmetics and personal care products such as scrubs, toothpaste, and shower gels, but also on artificial turf and other sports fields in the form of granulate material. These tiny plastic particles are flushed into the environment through wastewater and consequently end up in bodies of water.

- Secondary microplastics are created by the degradation of larger plastic products through the fragmentation of plastics already released into the environment due to solar radiation, weathering, and mechanical stresses. The largest sources are tire abrasion from vehicles on roads and microfibers created as a result of abrasion from washing synthetic clothing.

How can microplastic emissions be reduced?

The best way to avoid the release of primary microplastics is to avoid them entirely in products. If this is not feasible, natural ingredients can be used instead of plastic components. To drastically reduce the emission of microplastics, the European Commission adopted measures in September 2023, which are being successively implemented since October 2023 onwards. Loose glitter and microbeads, which are often used in cosmetics to remove dead skin cells, are already banned. Other sources of primary microplastics will be banned in the coming years, including various detergents, plasticizers, fertilizers, toys, medicines and granulate material for artificial sports surfaces. There is a transitional period of up to eight years to develop and realize possible alternative products[2]. The European Commission hopes that this measure will reduce microplastic emissions by 30 percent by 2030.

Unlike primary microplastics, reducing emissions of secondary microplastics is much more complex as secondary microplastics are not deliberately released. The reduction can be divided into four stages:

(i) The reduction of plastics in products and the use of plastic-free products reduces the possibility of the release of secondary microplastics during daily use.

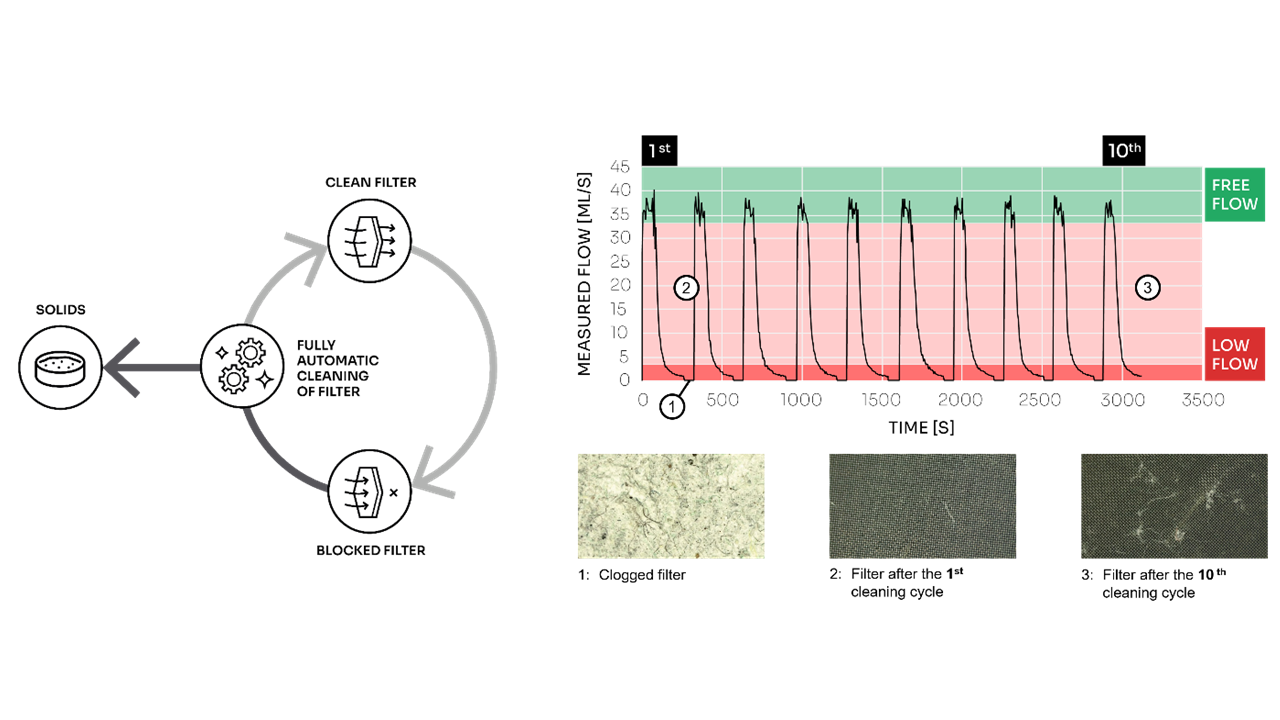

(ii) By capturing the microparticles directly at the source, the emission of products already available on the market or of products for which it is not possible to minimize the plastic content is reduced. Filters for washing machines to separate microfibers during washing cycles are an example of this.

(iii) If local separation is not feasible, the microparticles can be separated at centralized facilities such as wastewater treatment plants. However, modern wastewater treatment plants are not able to filter 100 per cent of the microplastics from the wastewater, which is why around 10 percent of the microplastics remain in the sewage sludge.

(iv) If microplastics have already been released into the environment, the only remaining option is to separate them directly from the environment, for example by filtering seawater and ocean water.

Helbling develops innovative solutions for the prevention of microplastics in the environment

Helbling is particularly involved in the first two stages in this area. This means that the reduction and replacement of microplastics and local separation are the starting points. An eco-design process is used in product development for this purpose, which takes environmental aspects into account in the design and integrates them there. This involves analyzing the environmental impact over the entire product life cycle (life cycle assessment). With such an approach, the potential volume of microplastics can be greatly reduced over the service life of an appliance, in line with the social, economic, and technical framework conditions.

The textiles industry is a major contributor to the release of microplastics, and this is an important lever for reduction. Many efforts are being made worldwide to curb microfibers in particular. France has become the first country in the world to pass a law requiring all newly sold washing machines to include a microplastic filter as standard from 2025. The aim here is to reduce the emission of microfibers caused by abrasion when washing synthetic textiles. Initial tests have shown that although existing filter solutions can separate microfiber and microplastic particles from the wastewater of a washing machine, the filter fails after only a short period of use. As part of internal development work, Helbling specialists in the areas of process development and process engineering were able to develop a filter cleaning process that offers separation of solids. This has the potential to increase the service life of microplastic filters by a factor of 100. This represents a breakthrough in terms of the marketability of microplastic filters and offers high innovation potential for all affected industries

Summary: A significant reduction in microplastics is technically feasible

Helbling has the expertise to integrate suitable technological solutions into innovative products to make a decisive contribution to the avoidance of microplastics. New laws and regulations on microplastics, such as the mandatory use of microfiber filters in washing machines in France, are an important driver of developments in this area. In this context, Helbling is adopting a clear focus on the development and implementation of efficient and effective sustainable filters. This is an important lever for dealing with this issue in the long term. Only by working together can the future be shaped sustainably.

Authors: Lukas Eberle, Marco Caduff, Christian Seiler

Main Image: AdobeStock